Fröling T4

Automatic Wood Chip and Wood Pellet Boiler

Efficiently Burn Wood Chips or Pellets

The Fröling T4 is a compact automatic wood chip boiler or wood pellet boiler. In its fourth generation of design, the T4 is the synthesis of over a decade of design improvements. It can safely and efficiently burn both wood chips up to 30% moisture content or wood pellets due to its well-designed, fully automatic system. Fröling also offers a wide range of fuel feeder systems for virtually all types of buildings. Cascading up to four Fröling T4 boilers is a great way to provide flexible heat load response throughout the seasons. Several sizes and types of rotary feed systems are available from Fröling. The Fröling T4 wood chip boiler is a reliable, surprisingly simple, yet high-tech and user-friendly heating system. Its 500,000 Btu/hr output is perfect for light commercial applications such as schools, businesses, offices, and warehouses.

Available Model

• Fröling T4 Boiler 130/150 - 443,000 to 512,000 Btu/Hr

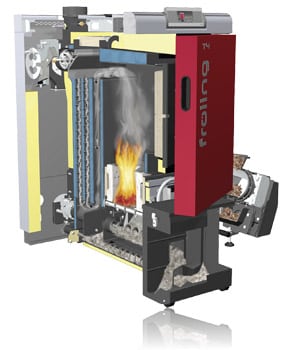

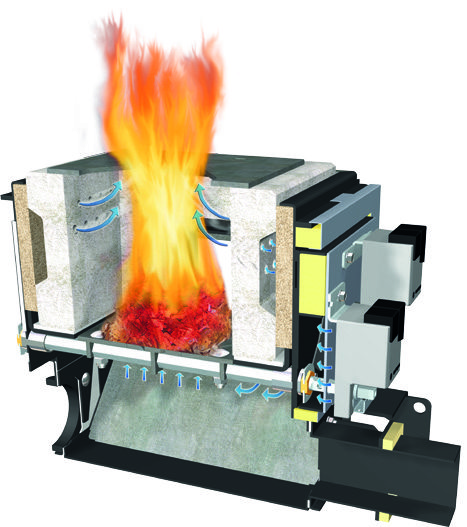

The T4 is made with a patented, long lasting silicon carbide combustion chamber. Extremely high combustion zone temperatures enable complete combustion while also allowing for quick re-ignition after short periods in idle mode. The three pass vertical heat exchanger removes fly ash from the exhaust stream and ensures maximum efficiency. Automatic ash augers are driven by a single motor, which utilizes multiple spur gears rather than multiple motors for mechanical simplicity and power conservation. The boiler arrives fully assembled with its heavily insulated jacket.

The Fröling T4 Model 130/150 is ASME certified.

Learn More - Video and Brochures

Boiler Features

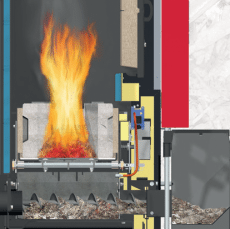

Silicon Carbide Combustion Chamber

The combustion chamber is fully lined with high-quality fireproof material (silicon carbide). The exceptionally hot combustion zone ensures optimal combustion and very low emissions. The patented shaping of the firebrick stones gives the air supply in the combustion chamber particularly good air tightness without the need to use expensive wearing seals. The new shape of the stones also simplifies the maintenance of the combustion chamber as they can be removed easily. Due to the hot combustion zone, after short periods in idle mode the fuel is automatically reignited by the residual embers. The igniter only starts after longer combustion pauses.

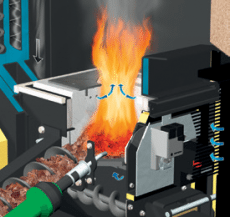

Smart Combustion Control for Safety and Low Emissions

Before ignition is allowed, a negative pressure switch must confirm safe operating conditions. Combining a negative pressure switch with an induced draft fan guarantees extremely high operating safety. The innovative control of air distribution in the combustion zone is a new feature. The primary and secondary air are optimally adjusted to the conditions in the combustion chamber with a joint actuator. This, combined with the lambda controller which comes as standard, ensures that emissions are kept to a minimum.

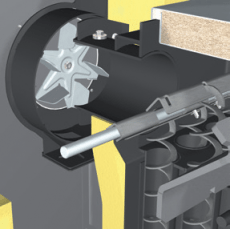

Variable Speed Induced Draft Fan

The standard speed-regulated induced draft fan, ensures the exact air quantity and constant under-pressure throughout combustion. By speed regulating, the induced draft fan assists with combustion control and adjusts boiler output. The induced draft fan is also very quiet and energy-saving.

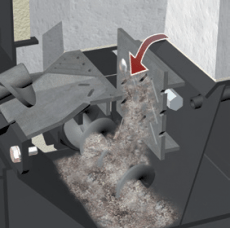

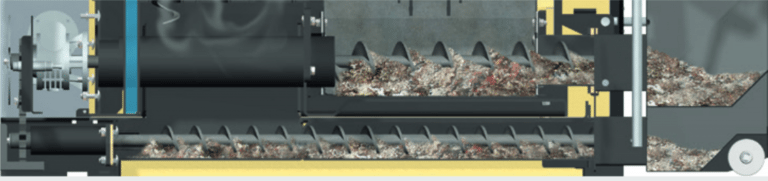

Smart Grate Technology

The combustion grate is divided in sections to ensure optimal combustion of wood chips or pellets. The tilting grates are built to not only distribute fuel within the combustion chamber, but to pivot vertically to clear ash away. The grates are made of a special high temperature steel alloy to guarantee a long service life.

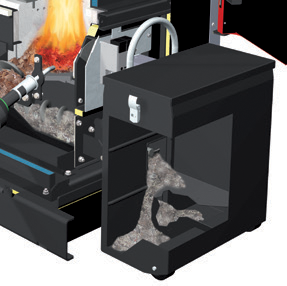

Easy Ash Removal

Ash is automatically emptied from the combustion chamber and the heat exchanger into the handy ash box using two separate ash augers, which are powered by a common motor. Additional auxiliary augers also powered by the same motor sweep the entire rear ash chamber, making for a robust ash removal system.

The boiler controller informs when the ash box should be emptied based on operation hours. Like a rolling suitcase, the ash box is easy to maneuver thanks to its transport wheels and extendable handle. A cover flap also ensures that no ash can fall out of the ash box during transportation.

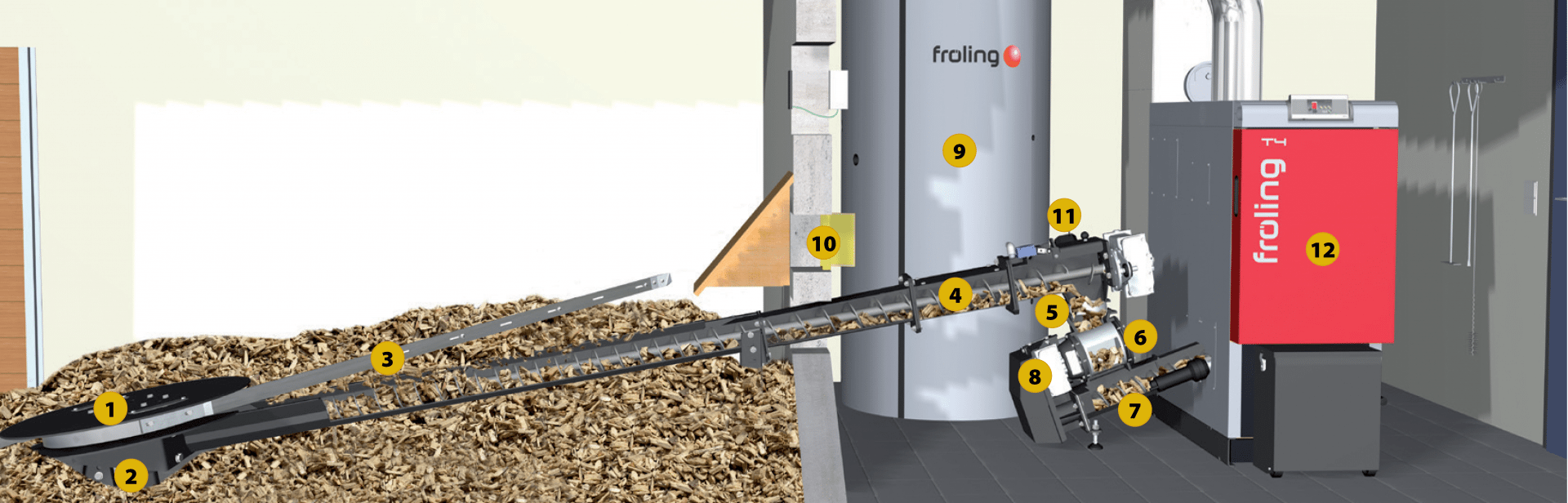

System Overview

- Robust agitator head.

- Maintenance-free agitator gearbox.

- Strong spring blade ensure even filling of the feed screw.

- Screw channel with progressive screw for smooth operation.

- Ball joint for continuously adjustable inclination of the feed screw.

- Patented twin-chamber rotary valve for top burn back protection.

- Sturdy stoker screw for reliable fuel feed with automatic turn control.

- Energy-saving spur gears.

- Thermal storage tank.

- Easy access to the sheer edge through an accessible opening.

- Gravity shaft cover with safety cut-off switch.

- T4 wood chip boiler.

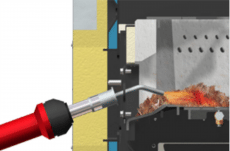

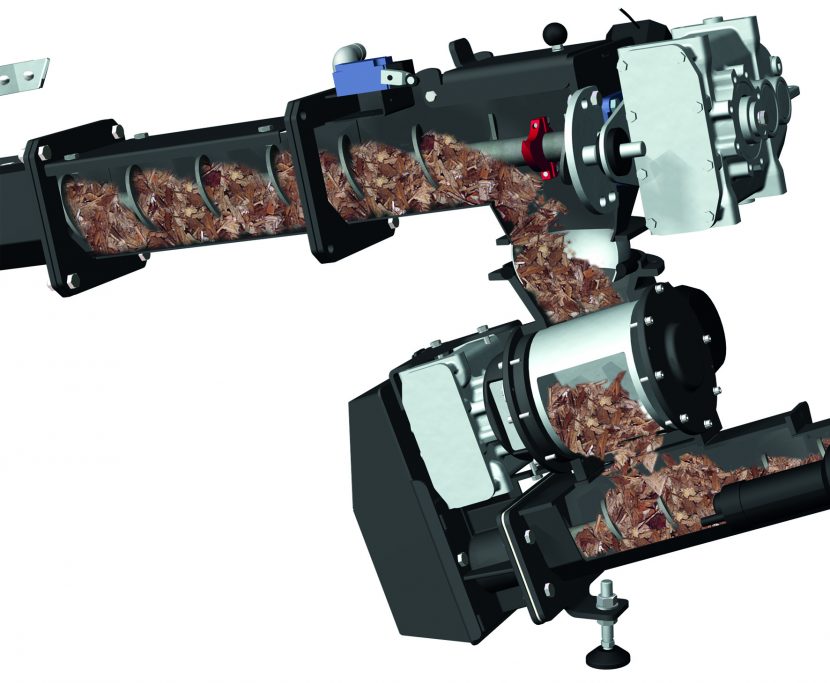

Heavy Duty Stoker and Flexible Ball Joint

The ball joint is a flexible connecting piece between the discharge screw and the stoker unit. Offering continuous adjustment of the inclinations (up to max. 15°) and angles, the ball joint enables an optimum adjustment to the space requirements. The highly compact stoker unit of the T4 together with the patented rotary valve guarantee top burn back protection and reliable fuel feed into the combustion zone. The stoker unit is driven jointly with the rotary valve by an energy-saving geared motor (spur gears), guaranteeing maximum energy efficiency.

Patented Twin-Chamber Rotary Valve

The patented twin-chamber rotary valve offers maximum operating safety. The rotary valve forms a reliable separation between the discharge system and the feed unit, providing optimal burn back protection. The advanced system design with two chambers ensures that the fuel is transported continuously to the combustion zone. This optimal fuel metering ensures the best possible combustion values. The two large chambers are especially suitable for transporting wood chips up to P45A (previously G50). The high-quality cutting edges can be replaced and also easily cut through coarser pieces. High resistance is recognized automatically. The rotary valve and screw move backwards (several times depending on the parameters set) until transport can be re-started. The rotary valve is extremely quiet and uses only minimal power.

Fröling Discharge Systems

The simple and effective design of Fröling's rotary agitator discharge systems ensures smooth operation. Any problematic materials (e.g. foreign debris) are automatically detected and removed by a reverse turn of the augers (turn control). The feed auger with progressive screw blade ensures low energy consumption.

Spring Blade Agitator

Maintenance free system maximum working diameter of 18' (5.5 meters). Designed for fuels that flow easily. (e.g. wood pellets, wood chips P16A/P45A to M35; previously G30/G50 to W35).

TGR/SGR Articulated Arm Rotary Agitator

Maintenance free system with patented design with a maximum working diameter of 19½' (6 meters). Designed for fuels requiring greater discharge power due to their limited ability to flow.

Connectivity

Fröling Connect software allows free remote monitoring and control from web enabled devices. You can read and modify the main status information and settings easily and conveniently on-line. It is also possible to store historic operating information and receive warnings such as when the ash box is full. It allows the owner of the heating system to enable additional users, for example a family member, neighbor, or service technician. Once the boiler is connected to the internet, the system can be accessed 24/7 from everywhere using a smartphone, tablet, or PC with web browser.

Project Summaries

Here are three working T4 and TX150 Boiler Project Summaries. For more project summary examples on pellet, wood chip, and cordwood boilers please click here.

Quality, Safety, and Performance

The Froling T4 wood chip/wood pellet boiler has won many international quality awards in Europe.

The Blue Angel

Plus X Award-International

ECOLABEL-Austria

T4 Wood Chip Boiler Features

• ASME Stamped Pressure Vessel

• 45 PSI Working Pressure

• Safety Tested and Listed

• For Commercial or Institutional Use

• Fully Automatic

• Fully Factory Assembled

• Silicone Carbide Combustion Chamber

• Lambda Controlled for Optimal Combustion

• Heavy Duty Automatic Ash Removal

• Cascade Control Available for Multiple Boilers

• Fully Insulated to Minimize Radiant Heat Loss

• Automatic Heat Exchange Cleaning

• True 3 Pass Heat Exchanger

• Fuel Can be Fed to the Right or Left Side of Boiler

• Speed-Controlled Induced-Draft Fan

• Industrial Quality Construction

• Energy-Saving Drives for Low Power Consumption

Discover Green Innovation

Changing the Way we Stay Warm

Claim your energy independence and start saving. Contact us to learn more.