The first Fröling Turbomat 500 (TM 500) has arrived in the USA! The TM 500 is a 1.7 mm Btu/hr. boiler capable of burning wood chips up to 45% moisture content or wood pellets. The boiler weighs over 18,000 pounds, in large part due to its heavily bricked firebox, which is necessary for wetter wood chips. The TM 500 uses a unique vertical heat exchanger that separates and drops out ash rather than allowing for ash to sit on horizontal heat exchanger surfaces. The TM 500 is designed to run 24 hours per day with no shutdowns for cleaning or re-fueling. The special alloy walking grate system needs no hoeing or scraping. The new TM 500 replaces another wood pellet boiler installed at Peoples Academy in 1982. The existing wood pellet boiler burned approximately 130 tons of wood pellets/year. The fuel feeding system is very simple for this installation. It consists of an exterior silo connected by a flex auger to a surge bin above the boiler’s feed auger.

The TM 500 will be replaced in the off-shoulder seasons by a Fröling P4 100 pellet boiler when heat demand is lower. The P4 100 feeds itself by vacuum from the same silo that supplies the TM 500.

Both pellet boilers were sold and installed by Sunwood Biomass of Waitsfield, VT (802) 583-9300.

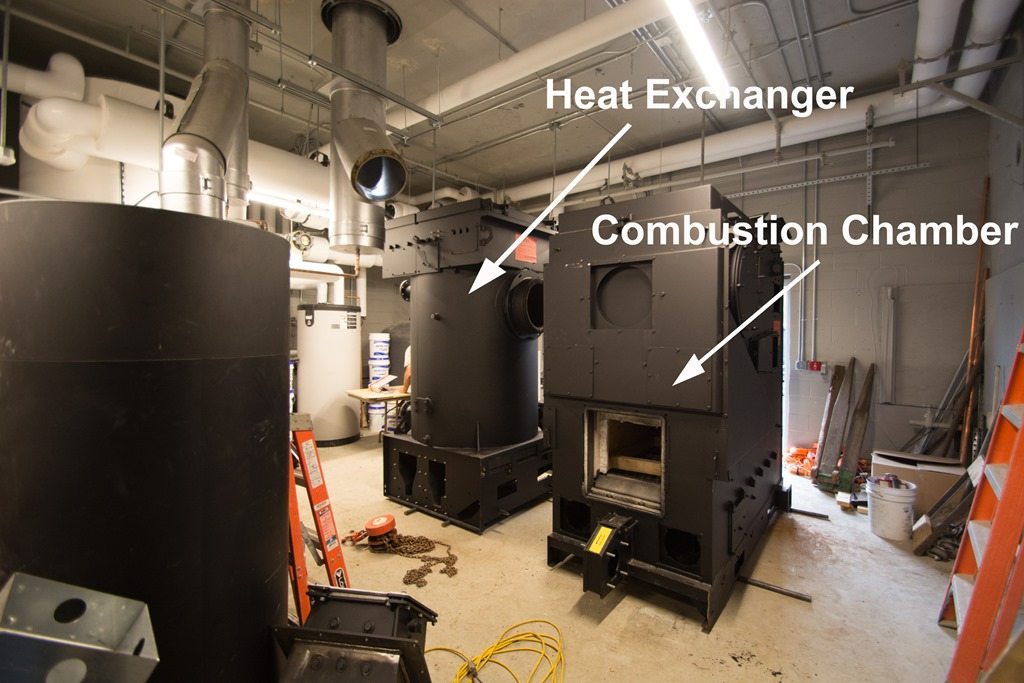

Below are some photos showing the assembly process.

The heat exchanger and the combustion chamber are joined together at the heat exchanger flange.

Necessary components are installed before insulation and jacket assembly.

Insulation batts are installed.

Jacket frame assembled.

Boiler jacket panels installed.

Draft fan and stoker feed components assembled.

Flue gas recirculation, ash containers, door switches, air actuators, electrical panels, etc installed.

Inside the combustion chamber (bottom). Here is a good view of the moving grate and the fireclay bricks. Amazingly, all of this was assembled at the factory before it was shipped (approx. dimensions 3’x7’.

Combustion chamber (top).

The combustion chamber is almost large enough to lose someone.

Below, is a cross-section view of the combustion chamber.

A Fröling P4 80/100 boiler (350,000 Btu/hr) was also installed for use during the shoulder heating season. This TM 500 will be burning wood pellets. An intermediate surge bin (pellet hopper) was installed to bridge between the silo’s auger and the boiler’s stoker fuel auger system.

The buffer tank and external fuel (wood pellets) silo.

Front view of Peoples Academy High School. The main building was built in 1928.